The brickmaking industry has undergone significant technological advancements in recent years, evolving from traditional manual methods to automated processes. The advent of automatic brick making machines has revolutionized brick production, offering numerous advantages over the traditional manual brick making machines. In this article, we will delve into the key differences between manual and automatic brick making machines, highlighting the benefits and drawbacks of each.

Manual Brick Making Machine vs. Automatic Brick Making Machine

Manual Brick Making Machine

A manual brick making machine, also known as a hand-operated brick press, relies primarily on human labor for its operation. It typically consists of a basic frame with a movable plunger or piston that compresses the brick material into the desired shape. Operators manually feed the raw material into the machine, control the compression process, and eject the formed bricks.

Advantages of Manual Brick Making Machine:

- Low Cost: Manual brick making machines are generally less expensive than automatic machines, making them an affordable option for small-scale brickmakers or those with limited budgets.

- Simplicity: The basic design and operation of manual brick making machines make them easy to understand and operate, even for individuals with limited technical knowledge.

- Portability: Manual machines are often smaller and lighter, allowing for easy transportation and deployment in remote or temporary locations.

Disadvantages of Manual Brick Making Machine:

- Low Productivity: The manual operation of the brick press limits the number of bricks that can be produced in a given timeframe. This can be a significant constraint for larger-scale operations seeking to meet high production demands.

- Labor-Intensive: Manual brick making machines require a significant amount of human labor, which can lead to fatigue and decreased efficiency over time.

- Inconsistent Quality: The quality of bricks produced by manual machines can vary depending on the skill and consistency of the operator. This can affect the overall strength and durability of the bricks.

Automatic Brick Making Machine

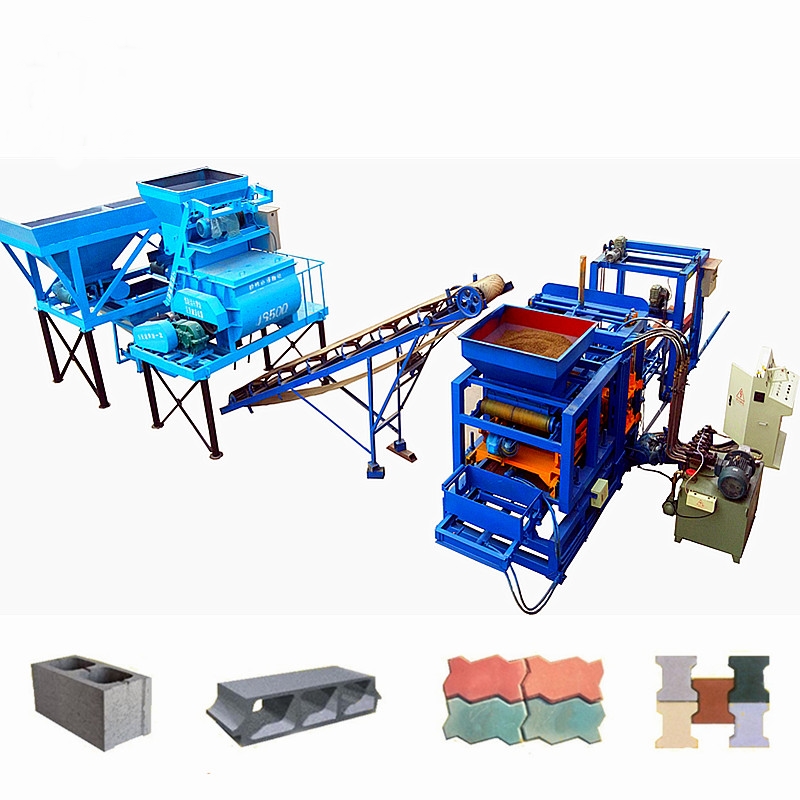

An automatic brick making machine employs advanced technology to automate the entire brick production process. It typically incorporates a conveyor belt system to feed the raw material into the machine, automatic compression mechanisms, and ejection systems to release the formed bricks. Additionally, automatic machines often have control systems that allow for precise adjustment of brick size, shape, and density.

Advantages of Automatic Brick Making Machine:

- High Productivity: Automatic brick making machines significantly increase production rates, enabling the production of large quantities of bricks in a short period of time.

- Reduced Labor: Automation reduces the need for manual labor, leading to cost savings and increased efficiency.

- Consistent Quality: Automatic machines produce bricks with consistent quality, ensuring uniform strength and durability.

- Flexibility: Automatic brick making machines offer greater flexibility in terms of brick size, shape, and material, allowing for customization to meet specific project requirements.

Disadvantages of Automatic Brick Making Machine:

- High Initial Cost: Automatic brick making machines are generally more expensive than manual machines, representing a significant investment for brickmakers.

- Technical Complexity: The advanced technology and automation features of automatic machines require a higher level of technical knowledge and expertise for operation and maintenance.

- Dependence on Electricity: Automatic machines rely on electricity for their operation, meaning they may be limited in their use in areas with unreliable power supplies.

Comparison

When comparing manual and automatic brick making machines, it is evident that each has its own unique set of advantages and disadvantages. The choice between the two ultimately depends on the specific needs and requirements of the brickmaker.

For small-scale operations or those with limited budgets, manual brick making machines may be a suitable choice. They offer a cost-effective solution for brick production, albeit with lower production rates and higher labor requirements. On the other hand, automatic brick making machines are ideal for large-scale operations seeking to maximize production efficiency and quality. Their high production rates and reduced labor costs make them a profitable investment in the long run.

However, it is worth noting that automatic brick making machines may require a higher initial investment and may not be suitable for all locations due to their dependency on electricity. Therefore, brickmakers must carefully consider their operational requirements, budget constraints, and available resources before making a decision.

Conclusion

In summary, both manual and automatic brick making machines have their respective advantages and disadvantages. Manual machines offer a low-cost and simple solution for small-scale brick production, while automatic machines provide higher productivity and consistent quality at a higher initial cost. The choice between the two ultimately depends on the specific needs and circumstances of the brickmaker. With the constant evolution of technology, it is likely that we will see further advancements in brick making machines, leading to even greater efficiency and quality in brick production.